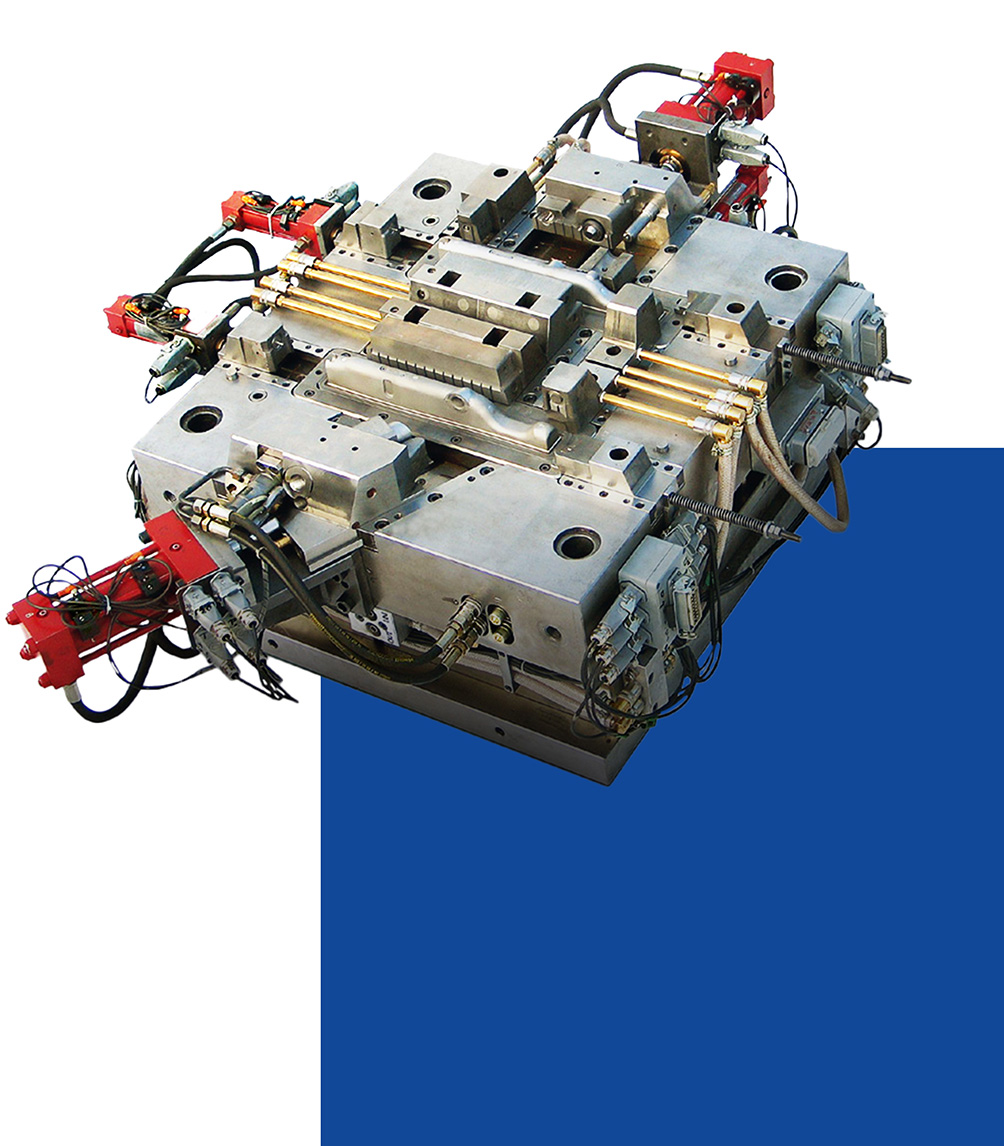

We offer our clients full support in the creation of tools for plastics processing.

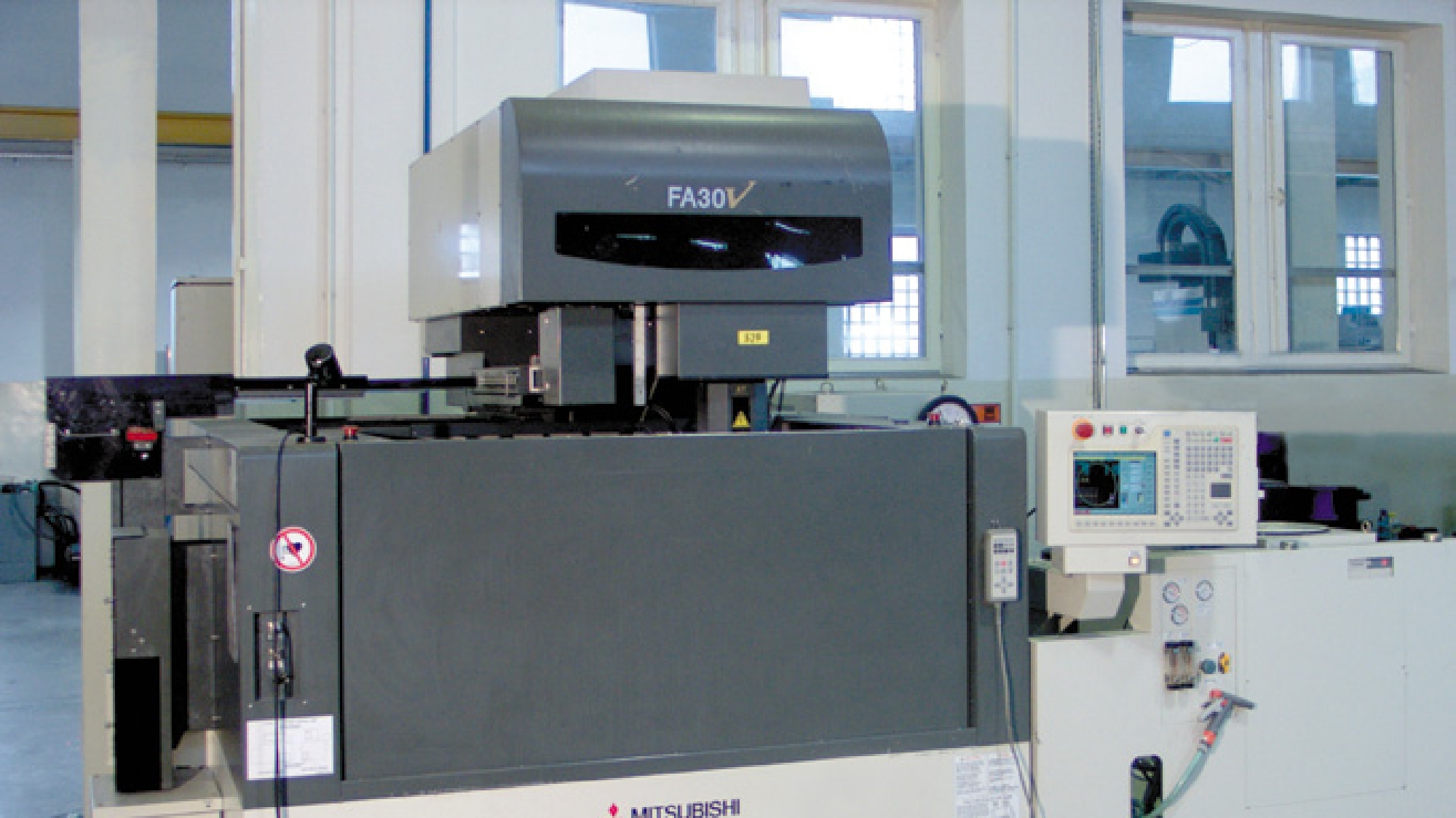

Starting from the preparation of the offer, through the design of the mould, the development of technology, the production of elements, to assembly of the mould and tests on our own machines with clamping forces from 25 to 900 tons, allowing for reliable testing of the mould, including production series.

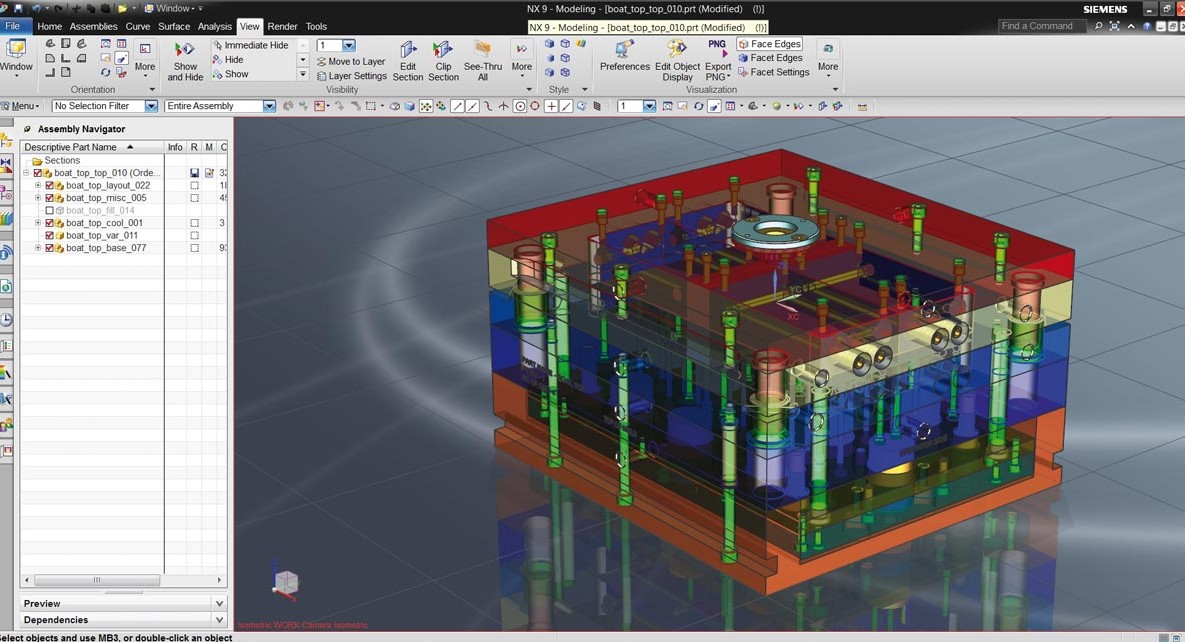

We have an experienced team of designers working on 8 CAD stations equipped with NX or CATIA programs.

The injection simulation software supports the calculation of part deformation and optimal mould design.

The design stage is carried out with the use of the most modern CAD / CAM software, which allows, already in the design phase, to eliminate errors and subsequent problems in the operation of the tool. Designing under the supervision of experienced designers takes place in full interaction with the client, thanks to which even the most complex tool are created efficiently and quickly.